AI on the edge

A finger on the pulse of your machine

Holistic monitoring through AI in field-level devices

In the course of digitalization and optimization of industrial processes, information on the current status of machines and systems, for example, is becoming increasingly important. This is because, in addition to data from regular operations, information on maintenance requirements and intervals or deviations is now important for the planning and execution of such production processes. But how can machine and plant operators be informed about changes on a situational basis?

Our English-language video can be foundhere.

The presented solution of SYS TEC electronic and PowerBrain.Shop shows by means of structure-borne noise analysis for machines and plants how data can be generated and processed correctly, meaningfully and up-to-date. Based on a practical example in the video of the same name, vibration patterns of recorded data during rotation can be used to map downtimes, regular operation as well as deviations or other anomalies, among other things.

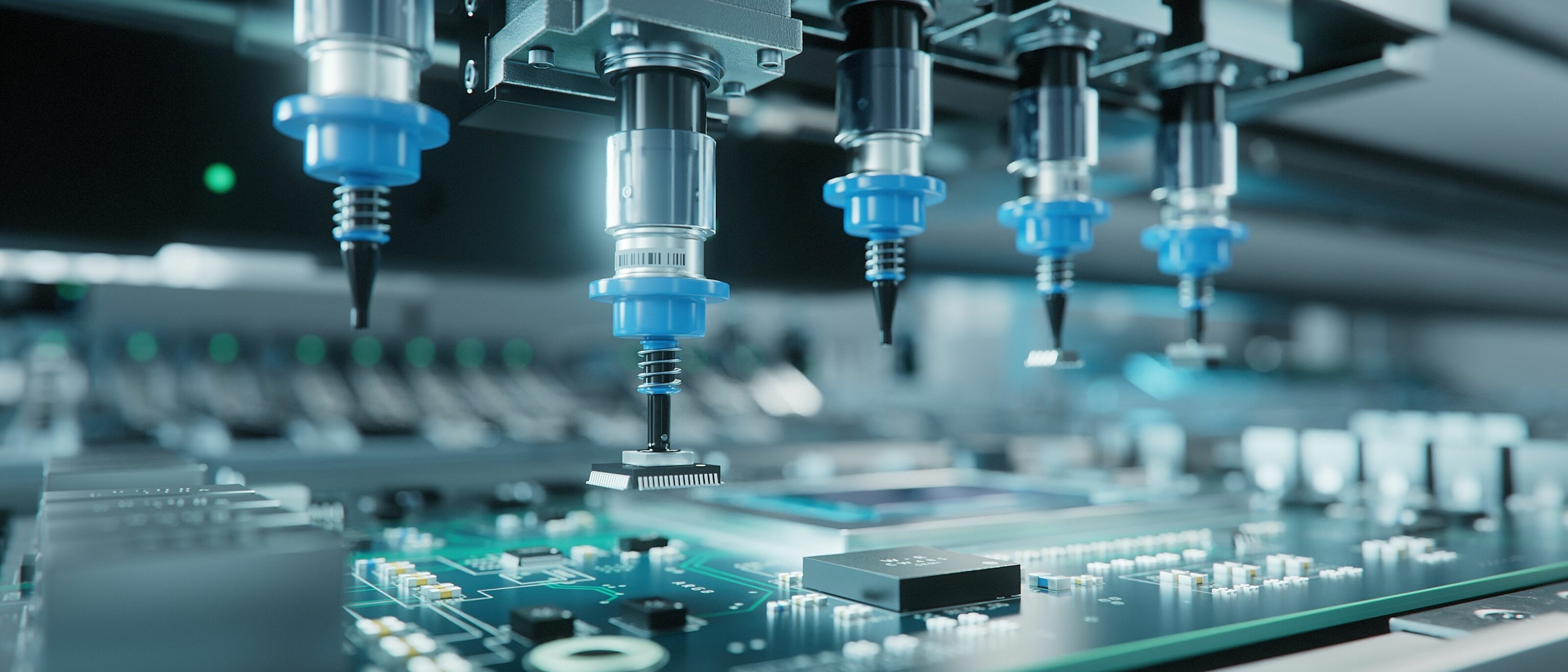

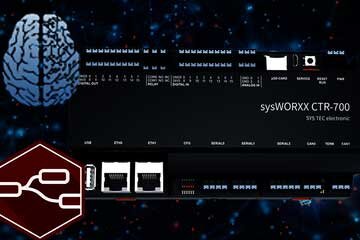

The recorded data is converted from the time to the frequency domain in the sysWORXX SSM-100 analysis module using Fast Fourier Transformation, or FFT for short. The frequency spectrum is transmitted together with the continuous RMS value to the controller, the sysWORXX CTR-700, and the linking of the data with the PowerBrain.Shop AI is implemented using Node-RED. The data of the FFT analysis itself is also sent via Node-RED to the AI PowerBrains, whose integration is done by so-called Docker containers. The controller thus serves as an execution platform and connects sensors and actuators with local artificial intelligence. In this way, autonomous artificial intelligence can be conveniently ported to field devices using AI PowerBrain technology.

Via an MQTT instance, the acquired and labeled data is communicated to the PowerBrains. In the AI itself, the information undergoes a check and is subsequently classified accordingly. A Node-RED interface designed by SYS TEC electronic allows for an uncomplicated integration and operation of the system, e.g. the training start of the Powerbrains and the monitoring of the progress. This is visually displayed in the monitor window.

Conclusion: FFT data are complex sensor data that can be usefully processed with the SYS TEC electronic/Powerbrain.Shop AI solution. This path enables direct on-site monitoring and control with low latency as well as an optionally available network and cloud connection for remote monitoring or control. Machine and plant operators benefit from AI as well as machine data monitoring and processing. Depending on the scenario, various deductions can be made regarding maintenance needs, wear or loosening of mechanical connections. Along with this, anomalies or damage can be detected at an early stage and countermeasures can be initiated.

The advantages of edge AI technology over cloud applications are obvious: the system operates autonomously and is attack-proof, can also be operated without Internet connectivity, and thus offers maximum cyber security. Since data sovereignty is self-evident, it remains on the machine of the operator/company and this can lead to cost savings, e.g. by eliminating costs for data aggregation from the field level to the cloud as well as transaction costs within the cloud.

Our solution is realized using our analytics module, our controller and the low-code Node-RED interface implemented there, and a PowerBrainShop AI.